| An Imagery of the i-VTEC Implementation |

|

|  |

|  |

| Contents[hide] |

| ||||||

| EGR Effect: By swirling back some of the exhaust air back into the combustion chamber, combustion temperature is lowered, and NOx output is reduced. |

哈哈

哈哈 好料哦

好料哦

| Information |

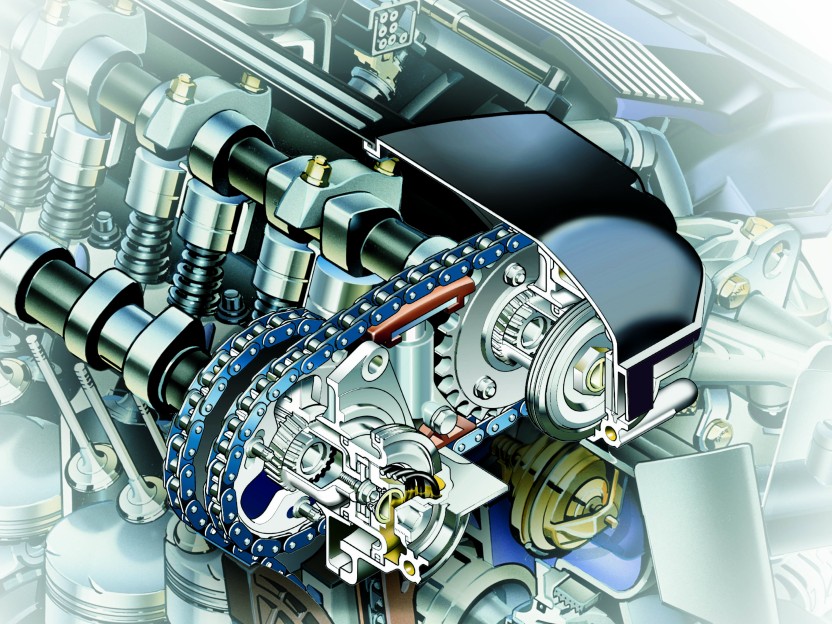

Valvetronic varies the timing and the lift of the intake valves. The Valvetronic system has a conventional intake cam, but it also uses a secondary eccentric shaft with a series of levers and roller followers, activated by a stepper motor. Based on signals formerly taken mechanically from the accelerator pedal, the stepper motor changes the phase of the eccentric cam, modifying the action of the intake valves.Valvetronic was introduced on the all-alloy 1.8-liter, 4-cylinder engine for the E46 316ti Compact, and it will subsequently be applied to most eight and 12-cylinder engines within a few years. The new E65 7 Series has Valvetronic engines.

| Here's how it works: |

At light throttle, the throttle butterfly partially or even nearly closes. The pistons are still running, taking air from the partially closed intake manifold. The intake manifold between the throttle and the combustion chamber has a partial vacuum, resisting the [词语过滤-#17]ing and pumping action of the pistons, wasting energy. Automotive engineers refer to this phenomenon as "pumping loss". The slower the engine runs, the more the throttle butterfly closes, and the more energy is lost.Valvetronic minimizes pumping loss by reducing valve lift and the amount of air entering the combustion chambers.

Compared with conventional twin-cam engines with finger followers, Valvetronic employs an additional eccentric shaft, an electric motor and several intermediate rocker arms, which in turn activates the opening and closing of valves. If the rocker arms push deeper, the intake valves will have a higher lift, and vice-versa. Thus, Valvetronic has the ability to get deep, long ventilation (large valve lift) and flat, short ventilation (short valve lift), depending on the demands placed on the engine.Operating Parameters:

| What is MIVEC? In the early ‘90s, Mitsubishi Japan introduced a valve control system to combat Honda’s VTEC design. This system is labelled MIVEC (Mitsubishi Innovative Valve and Lift Electronic Control System).  In its simplest form, MIVEC switches between two different intake and exhaust cam lobes depending on engine rpm. At low rpm, the valves receive relatively modest lift and opening duration. At high rpm, the secondary cam lobe is engaged and the valves receive greater lift and duration (which results in increased overlap). The purpose of the secondary cam lobe is to deliver greater engine breathing and the ability to maintain torque at very high rpm (which means greater power). The MIVEC system achieves its high power without the driveabililty, fuel consumption and emissions trade-offs typical in a conventional engine. In addition to the base MIVEC principle, Mitsubishi also released a sophisticated MIVEC-MD (Modular Displacement) system in the ‘90s.  The MD system is an early form of cylinder deactivation which involves closing the intake and exhaust valves at light engine load. This means the driver must open the throttle further to maintain power and, as a result, pumping losses are reduced and active cylinder pressures are increased. This results in greater efficiency and fuel economy. Depending on conditions, the MIVEC-MD system can reduce fuel consumption by 10 – 20 percent. |

| HOME > Corporate Info > About Us > Technology > Driving Fun > MIVEC | ||||||

MIVECRemarkable MIVEC Engine makes power performance and environmental protection compatible MIVEC = Mitsubishi Innovative Valve timing Electronic Control system

|

| |||||||||||||||||||||||||||||||||||

A balance between increasing engine performance, improving fuel economy, reducing emissions and stabilizing idle is difficult to achieve. In its 3.0-liter 6-cylinder and turbocharged 2.5-liter 4-cylinder engines, Subaru strikes that balance using the Active Valve Control System (AVCS). What AVCS Does and Its Effects

The camshaft is a very precise engine component, with lobes that open and close the intake and exhaust valves with the critical timing required for the 4-stroke cycle. AVCS changes the timing of the intake valves by adjusting the positions of the camshafts based on inputs from various sensors in the powertrain. The system varies when the camshaft lobes open and close the intake valves during the 4-stroke cycle. The effects of variable valve control include greater power through a wider range of engine speeds, improved fuel economy and reduced emissions. But to better understand how it works, let’s start with engine basics – the 4-stroke engine cycle. The 4-Stroke Cycle Most of today’s automotive gasoline engines function via a 4-stroke cycle. Engine components continuously cycle through four strokes, named for their functions of intake, compression, power and exhaust. AVCS affects the roles of the camshafts in this process. Actuation is mechanical, by direct contact or through a combination of lifters, tappets and/or pushrods, depending on engine design. How the camshafts are designed essentially gives engines their personalities. Camshafts in Subaru engines are belt-driven (4-cylinder) or chain-driven (6-cylinder) by the crankshaft. Intake valves open to let the air into the combustion chamber, and exhaust valves open to let out the exhaust gases. AVCS operation affects the intake valve timing or at exactly what point each valve opens and closes. Overall, intake- and exhaust-valve operation during the 4-stroke cycle follows this pattern:  However, there are nuances in operation, and that’s where AVCS plays a part. In the 4-stroke sequence, the exhaust cycle immediately precedes the intake cycle. Overlapping the timing of the closing of the exhaust valves and the opening of the intake valves can help the engine perform better under heavy loads, but not under light loads. AVCS continuously varies this overlap through an infinite number of positions. Overlap ranges between a slight overlap (“retard” position) through as much as 35 degrees of the crankshaft rotation (“advance” position). AVCS Components Variable valve timing is controlled through a hydraulic system that takes instruction from a system of electronic controls. Engine management computer: Electronic control is by the engine management computer, which uses input from a number of engine sensors to determine the ideal position for the camshafts. The sensors include those that measure airflow into the intake system, coolant temperature, throttle position and camshaft position. Oil control valve: The control unit then actuates changes through an oil control valve positioned at each intake camshaft sprocket. The oil control valve uses oil pressure from the engine to advance and retard the intake camshafts via the AVCS actuator. Actuator: Mounted in the chain- or belt-driven drive sprocket, the actuator is fitted directly to the camshaft. Chambers in the actuator allow oil pressure to advance or retard it within the timing-belt sprocket. The oil fills the chambers and pushes against three lobes to turn the actuator and the camshaft on its axis. AVCS – Bringing It All Together At idle: The intake valves open just after the piston reaches the top of the cylinder (called “top dead center” or TDC; BDC refers to “bottom dead center”) at the end of the exhaust stroke, as the piston begins the intake stroke. The exhaust stroke creates negative pressure within the chamber, and intake air enters the cylinder with positive pressure “to fill the void.” There is very little or no overlap between the exhaust and the intake strokes.  Retarding valve timing improves the smoothness of engine operation at idle, which tends to be a problem area in high-performance engines without variable valve control. (If you remember the muscle cars of the 1960s and 1970s, you may recall how roughly they idled.) | |||||||||||||||||||||||||||||||||||

At light-to-medium engine loads: From idle through medium engine loads, AVCS advances the intake valves to begin opening during the last part of the exhaust stroke, when the exhaust valves are still slightly open. Some of the pressure created during the exhaust stroke flows into the intake manifold, having the effect of exhaust gas recirculation (EGR). The intake valves also close earlier during the intake stroke.  Advancing valve timing for some overlap helps reduce the level of harmful oxides of nitrogen in the exhaust. It also improves volumetric efficiency, which is an indication of how well air flows through the engine. The greater the efficiency, the stronger the engine’s performance. At heavy engine loads: When the engine is used aggressively for greatest performance, AVCS advances the intake valves further to open even sooner during the exhaust stroke. This produces a scavenging effect – that is, intake airflow helps clear the cylinder of exhaust gas. It also closes the intake valves sooner on the compression stroke.  This results in improved volumetric efficiency and helps to generate higher power output. Overall, varying valve timing helps the engine to develop power more evenly between low and high speeds. At the same time, it improves engine idle and lowers exhaust emissions. Thoroughly Modern AVCS AVCS contributes to the driveability and performance of many Subaru engines. It provides greater power, smoother operation and fewer harmful emissions through a thoroughly modern engine technology. | ||

| ||

原帖由 ckerz 于 2009-7-7 06:18 PM 发表

好像网址是 http://www.youtube.com/watch?v=sV3gD6LF5xM 你只需要copy sV3gD6LF5xM就好。

原帖由 千叶 于 2009-7-8 12:37 PM 发表

( ⊙o⊙ )哇

看到两位有心人士

热血为引擎区贡献

值得嘉奖~

可惜我只是会员

不能为你们加分

但是还是掌声鼓励鼓励

干得好~em0020

原帖由 毛毛小子 于 2009-7-8 09:38 PM 发表

哈哈哈,我只是把你夸张化吧了啦,别生气.....>"<

之前我也记得你在做版主时候几乎是很少出现过....^_^

现在可好了。。。

谁炒你鱿鱼??KENNY ?

原帖由 毛毛小子 于 2009-7-8 10:53 PM 发表

哈哈

可是以前我都没有射过你......

我经常看到很多流氓上来jbtalks然后在那里射来射去,炮来炮去...

PS: 楼上我不是有些你是爱车一族版主了吗?怎么还有人问=="

原帖由 千叶 于 2009-7-9 12:29 PM 发表

贴钱~

加买我以前家里不能上网

去坛主的CC送钱给他帮他管~~em0023 em0023 em0041

回想起来

我那是还真笨呐~em0046

原帖由 千叶 于 2009-7-9 05:35 PM 发表

现在的就不懂啦

以前都是响应号召而去的

为建设JBT嘛~

虽然很多人觉得我在JBT没什么建设

肯尼才有建设~

O(∩_∩)O哈!em0046

原帖由 毛毛小子 于 2009-7-9 06:32 PM 发表

呵呵。。。。

我的注册日期也不会很新啊.....

我很早就知道JBTALKS了。。

以前是http://jbtalks.com

疑问。。。

疑问。。。

不想说了

不想说了

不过是二轮的!

不过是二轮的!

| 欢迎光临 JBTALKS.CC (https://www.jbtalks.cc/) | Powered by Discuz! X2.5 |