- 分享

- 0

- 人气

- 0

- 主题

- 5

- 帖子

- 4372

- UID

- 227440

- 积分

- 4508

- 阅读权限

- 22

- 注册时间

- 2009-5-15

- 最后登录

- 2014-7-1

- 在线时间

- 5992 小时

|

History

[edit] Steam engines

The first variable valve timing systems came into existence in the nineteenth century on steam engines. Stephenson valve gear, as used on early steam locomotives, supported variable cutoff, that is, changes to the time at which the admission of steam to the cylinders is cut off during the power stroke. Early approaches to variable cutoff coupled variations in admission cutoff with variations in exhaust cutoff. Admission and exhaust cutoff were decoupled with the development of the Corliss valve. These were widely used in constant speed variable load stationary engines, with admission cutoff, and therefore torque, mechanically controlled by a centrifugal governor and trip valves. As poppet valves came into use, simplified valve gear using a camshaft came into use. With such engines, variable cutoff could be achieved with variable profile cams that were shifted along the camshaft by the governor. [1].

[edit] Aircraft

Some versions of the Bristol Jupiter radial engine of the early 1920s incorporated variable valve timing gear, mainly to vary the inlet valve timing in connection with higher compression ratios.[1] The Lycoming R-7755 engine had a Variable Valve Timing system consisting of two cams that can be selected by the pilot. One for take off, pursuit and escape, the other for economical cruising.

[edit] Automotive use

Fiat was the first auto manufacturer to patent a functional automotive variable valve timing system which included variable lift. Developed by Giovanni Torazza in the late 1960s, the system used hydraulic pressure to vary the fulcrum of the cam followers (US Patent 3,641,988). The hydraulic pressure changed according to engine speed and intake pressure. The typical opening variation was 37%.

n September 1975, General Motors (GM) patented a system intended to vary valve lift. GM was interested in throttling the intake valves in order to reduce emissions. This was done by minimizing the amount of lift at low load to keep the intake velocity higher, thereby atomizing the intake charge. GM encountered problems running at very low lift, and abandoned the project.

Alfa Romeo was the first manufacturer to use a variable valve timing system in production cars (US Patent 4,231,330). The 1980 Alfa Romeo Spider 2.0 L had a mechanical VVT system in SPICA fuel injected cars sold in the United States. Later this was also used in the 1983 Alfetta 2.0 Quadrifoglio Oro models as well as other cars. The system was engineered by Ing Giampaolo Garcea in the 1970s.[2]

Honda's REV motorcycle engine employed on the Japanese market-only Honda CBR400F in 1983 provided a technology base for VTEC.

In 1987,[citation needed] Nissan developed their own form of VVT with the VG30DE(TT) engine for their Mid-4 Concept. Nissan chose to focus their NVCS (Nissan Valve-Timing Control System) mainly on torque production at low to medium engine speeds, because, the vast majority of the time, automobile engines will not be operated at extremely high speeds. The NVCS system can produce a smooth idle and high amounts of torque at low to medium engine speeds. The VG30DE engine was first used in the 300ZX (Z31) 300ZR model in 1987. It was the first production car to use electronically controlled VVT technology.

The next step was taken in 1989 by Honda with the VTEC system. Honda had started production of a system that gives an engine the ability to operate on two completely different cam profiles, eliminating a major compromise in engine design. One profile designed to operate the valves at low engine speeds provides good road manners, low fuel consumption and low emissions output. The second is a high lift, long duration profile and comes into operation at high engine speeds to provide an increase in power output. The VTEC system was also further developed to provide other functions in engines designed primarily for low fuel consumption. The first VTEC engine Honda produced was the B16A which was installed in the Integra, CRX, and Civic hatchback available in Japan and Europe. In 1991 the Acura NSX powered by the C30A became the first VTEC equipped vehicle available in the US. VTEC can be considered the first "cam switching" system and is also one of only a few currently in production.

In 1991, Clemson University researchers patented the Clemson Camshaft which was designed to provide continuously variable valve timing independently for both the intake and exhaust valves on a single camshaft assembly. This ability makes it suitable for both pushrod and overhead cam engine applications.[3]

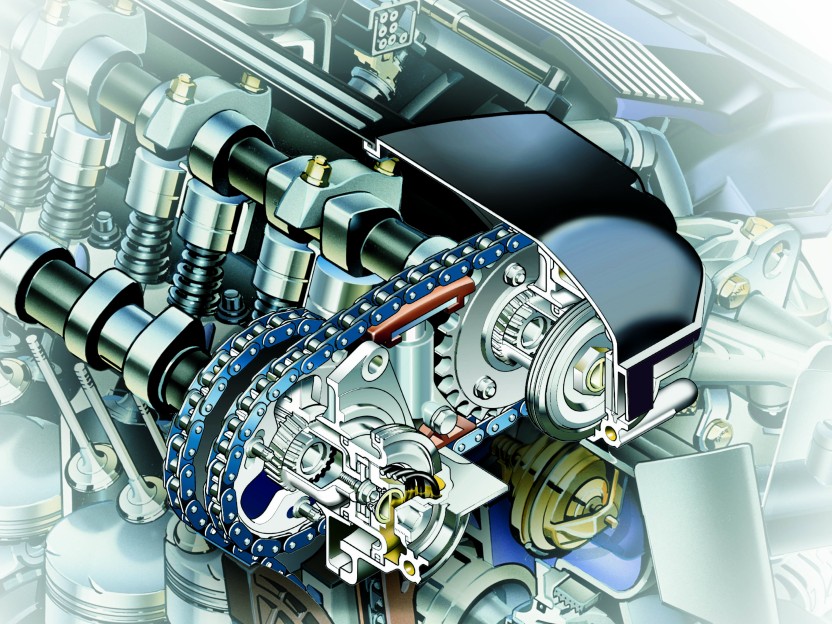

In 1992 BMW introduced the VANOS system. Like the Nissan NVCS system it could provide timing variation for the intake cam in steps (or phases), the VANOS system differed in that it could provide one additional step for a total of three. Then in 1996 the Double Vanos system was introduced which significantly enhances emission management, increases output and torque, and offers better idling quality and fuel economy. Double Vanos was the first system which could provide electronically controlled, continuous timing variation for both the intake and exhaust valves. In 2001 BMW introduced the Valvetronic system. The Valvetronic system is unique in that it can continuously vary intake valve lift, in addition to timing for both the intake and exhaust valves. The precise control the system has over the intake valves allows for the intake charge to be controlled entirely by the intake valves, eliminating the need for a throttle valve and greatly reducing pumping loss. The reduction of pumping loss accounts for more than a 10% increase in power output and fuel economy.

Ford began using Variable Cam Timing in 1998 for Ford Sigma engine. Ford became the first manufacturer to use variable valve timing in a pickup-truck, with the top-selling Ford F-series in the 2004 model year. The engine used was the 5.4L 3-valve Triton.

In 2005 General Motors offered the first Variable Valve timing system for pushrod V6 engines, LZE and LZ4.

In 2007 DaimlerChrysler became the first manufacturer to produce a cam-in-block engine with independent control of exhaust cam timing relative to the intake. The 2008 Dodge Viper uses Mechadyne's concentric camshaft assembly to help boost power output to 600 bhp (450 kW).

In 2009 Fiat Powertrain Technologies introduced the Multiair system in Geneva Motor Show. The Multiair is a hydraulically-actuated variable valve timing system, which gives full control over valve lift and timing. The new technology will be available in Alfa Romeo MiTo starting from September 2009.[4] |

|

IP卡

IP卡 狗仔卡

狗仔卡

发表于 2009-7-6 10:55 PM

发表于 2009-7-6 10:55 PM

收藏

收藏 提升卡

提升卡 置顶卡

置顶卡 沉默卡

沉默卡 喧嚣卡

喧嚣卡 变色卡

变色卡 显身卡

显身卡

哈哈

哈哈 好料哦

好料哦